The Operating Principle of LEM Magnetic Field Sensor and the Rogowski Coil

A Rogowski coil is a sensor used to measure electric currents or changing magnetic fields. It is especially used in alternating current (AC) circuits. The Rogowski coil determines the value of the electric current by measuring the voltage induced by the action of the magnetic field. Rogowski coils are used in many fields such as energy systems, industrial applications, laboratory tests and researches. They provide high sensitivity and flexibility in the measurement of electrical current, making them optimum sensors in such applications.

Why is Rogowski Coil Used in the Measurement of Electric Current and Magnetic Field?

- Sensitivity: Rogowski coils measure electrical current with high precision. They provide more precise results compared to other methods, particularly when measuring high currents and rapidly changing currents.

- Minimum Intervention: Rogowski coils can easily be inserted into the circuit to be measured, with minimum intervention. This ensures that measurements can be made without affecting the functioning of the circuit to be measured.

- Wide Measuring Range: They can be used in a wide range to measure different current values. Some models can even measure very high currents.

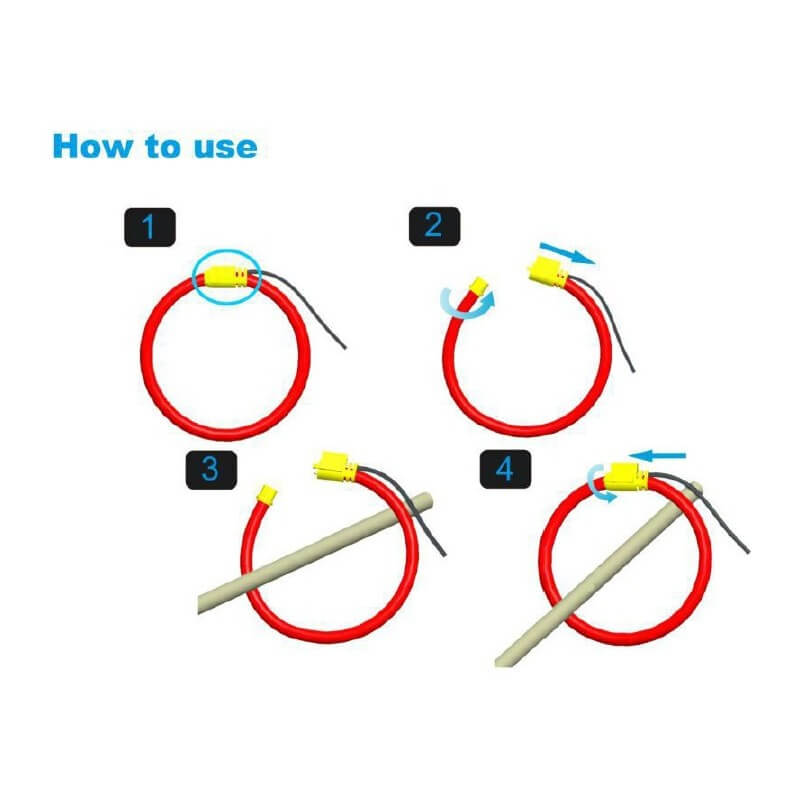

How is Rogowski Coil Used?

- Placing: Rogowski coil is wound around the current-carrying conductor that will be measured. The winding number and geometry of the coil are selected depending on the measured current value and frequency.

- Coupling: The output of the coil is connected to the measuring device or data collecting system. This output represents the voltage induced by the action of the magnetic field.

- Calibration: Rogowski coils are usually subject to a calibration process before being used. This allows the coil to make accurate measurements.

- Data Collection: After the coil is connected, the voltage induced by the magnetic field action is measured and these voltage values are converted into current values. These data are used to analyze the current’s magnitude and waveform.

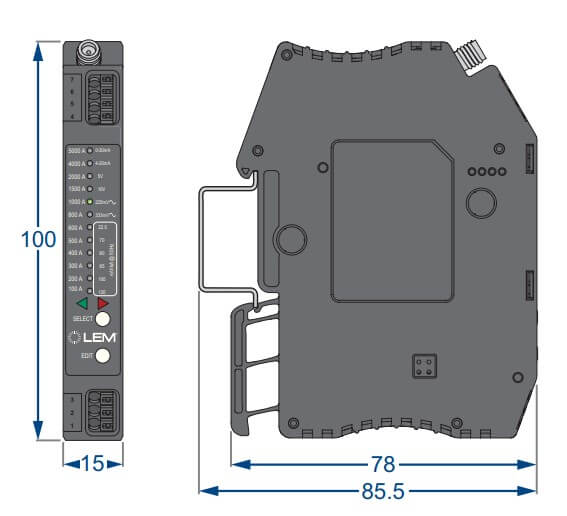

LEM AI-PMUL Configurable Rogowski Coil Signal Regulator

The universal Rogowski coil integrator AI-PMUL is compatible with LEM’s flexible clip-on ART and ARU coil series. Its design relies on the latest technology to combine dynamic range, precision and flexibility of use. It offers both RMS and instant outputs. The AI-PMUL is mounted on the DIN rail and can be used for multiphase applications without any gap with its low power consumption.

Input Signal

- Rogowski coil precision: 22.5, 70, 80, 85, 100, 120 mV/kA (@ 50 Hz)

- Current measurement range: 100, 200, 300, 400, 500, 600, 800, 1000, 1500, 2000, 4000, 5000A

- Over-current measurement range, 120% selected range (over-current indicator with LED)

- Rated frequency 50/60 Hz

- Frequency bandwidth (- 3dB) 4 ~ 1600Hz

Output Signal

- Current (Actual RMS measurement): 0-20mA, 4-20mA

- Voltage (Actual RMS measurement): 0-5V, 0-10V

- Voltage (Instantaneous Value): 0-225mVac, 0-333mVac

- Load impedance current output: ≤500Ω / Output Voltage: ≥1kΩ

- Linearity error ≤ 0.1%

General Properties

- Supply voltage: 24Vdc (10-32Vdc)

- Current consumption: 100mA (24Vdc)

- Insulation test voltage: 1500V, 50Hz, 1 min.

- Protection type: IP20

Applications

- MV/LV substations: transformer status monitoring

- Power measurement: active power calculation for current measurement

- Building sub-measurement: energy efficiency monitoring, consumption analysis and cost allocation

- Power quality monitoring: electrical loads and distribution system equipment

- Fault detection, isolation and repair (FDIR)

- Remote terminal units (RTU)

- MV & LV Measurement and Monitoring

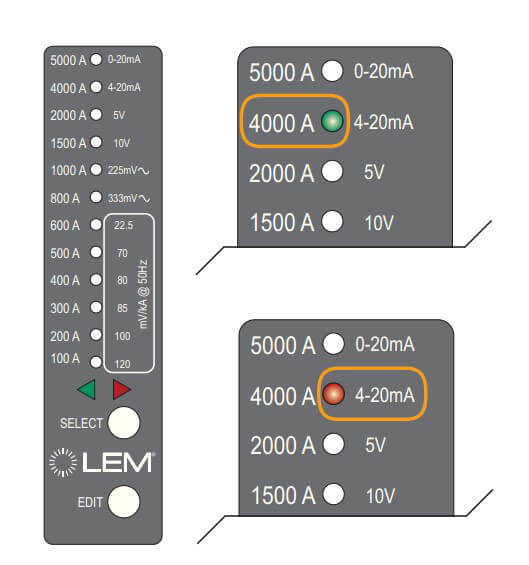

The new integrator AI-PMUL covers all the ratings you may expect in a single universal product. The simple configuration and the ability to see the status on the front panel allows you to configure it with ease. Together with our ART and ARU Rogowski coils, it offers a universal measurement and monitoring solution up to 5000A to meet your urgent needs and for the possible future development of your network.

The AI-PMUL versatility can be achieved with a simple, reliable and error-free configuration system using an ergonomic push button and visible dual-color LEDs, where green is for current range selection and red is for input sensitivity and output selection.

LEM ARU Series

Outdoor type Rogowski coil with flexible clip for electronic measurement of AC current with galvanic decoupling between primary circuit (power) and secondary circuit (measurement). The patented Perfect Loop Technology significantly reduces both the error caused by the position of the measured conductor within the gap and the error caused by the proximity of external conductors. With its reinforced design, the ARU can be adapted to several rough environments such as outdoor facilities or underground medium voltage distribution stations.

Product Features

- Designed for outdoor use (acc. to UV, water, dust and ice standards)

- High sensitivity 100mV/kA (@50Hz)

- Flexible circular shape

- Rated insulation CAT III 1000 V PD2, CAT IV 600 V PD3 Class 0.5 (IEC 61869-10)

- Protection rating: IPX8

- ∅125, 175, 250 and 300mm detection range

- Operating temperature: -40~+80°C

- 3m to 6m cable length

- With its innovative patented coupling, it greatly reduces positioning error

- With its built-in guard, it provides improved measurement accuracy at low primary currents.

Applications

- Outdoor substations

- Distribution transformer Monitoring

- Medium voltage isolated cable distribution

- Underground substations

- Pole-mounted transformers

- Low voltage lines

- Distribution system equipment

LEM ART Serisies

Rogowski coil with flexible clip for electronic measurement of AC current with galvanic decoupling between primary circuit (power) and secondary circuit (measurement). The patented Perfect Loop Technology significantly reduces both the error caused by the position of the measured conductor within the gap and the error caused by the proximity of external conductors.

Product Features

- The most sensitive coil on the market: Class 0.5 (IEC 61869-10)

- Very low positioning error

- Small outdoor area effect

- Low sensitivity (22.5mV/kA) to have a very thin coil for indoor applications

- It is electrostatically isolated to improve the common mode attenuation of the integrator.

- Protection rating: IP57

- ∅70, 125, 175, 250 and 300mm detection range

- Operating temperature: -40~+80°C

- 1.5m to 6m cable length

- The cable end is equipped with SMA male connector.

Applications

- Secondary distribution substations

- Distribution transformer monitoring

- Phaser measurement units (PMU)

- Commercial and industrial buildings

- Measurement and sub-measurement

- Demand response (DR)

- Distribution system equipment