Isabellenhütte, a leading company in the field of precision measurement technology, manufactures electrical resistance and thermoelectric materials for temperature measurement, as well as passive components for the automotive, electrical and electronics industries. Setting the standards for current, voltage and temperature measurement, Isabellenhütte’s products are used in a wide range of applications, from automobiles and commercial vehicles to hybrid and electric vehicles, industrial and regenerative energy generation systems.

Precision and Power Resistors

There are two basic types of resistors used for different purposes in electronic circuits. The characteristics, areas of application and manufacturing technologies of these are different. Below are the detailed descriptions of these types of resistors:

Precision Resistors

- High Accuracy: Precision resistors operate at values very close to the nominal resistance value. They are usually engineered with tolerances of ±0.1%, ±0.01% or even lower.

- Low Temperature Coefficient (TCR): They offer resistance values that are not affected by temperature changes. The TCR can usually be between ±1 ppm/°C and ±50 ppm/°C.

- Long-Term Stability: They show little change in resistance values over time, ensuring a long-lasting and reliable performance.

- Low Noise: They have minimal noise transmission in electronic circuits, ideal for precise measurements.

Power Resistors

- High Power Capacity: They have the capacity to carry a high electrical power and current. The Watt levels can usually vary from a few watts to hundreds of watts.

- Heat Dissipation: Power resistors are made of materials that are resistant to high temperatures and their designs optimize heat dissipation.

- Durability: They are resistant to harsh working conditions and usually big in size.

- Various Tolerances: Since they are used for managing the power rather than the sensitivity, their tolerance is usually wider.

Special Alloy Materials Developed by Isabellenhütte

MANGANIN

Manganin, developed by Isabellenhütte about 100 years ago, is an alloy consisting mainly of the elements manganese (Fr), copper (Cu) and nickel (Ni). It is used as a resistor material. It distinguishes with its low temperature coefficient (±20 ppm/°C) and high stability. It also has a low thermoelectric power coefficient with copper (about 1 µV/°C), making it ideal for precise measurements. It is resistant to corrosion and shows high stability over time.

Manganin is widely used in precision measuring instruments, reference resistors, shunt resistors, electrical measuring instruments and calibration equipment. It is manufactured with wire drawing and rolling methods, and its properties are preserved by applying a meticulous heat treatment process.

Its advantages include low TCR, high stability, corrosion resistance and low thermoelectric power coefficient. On the other hand, it can be more costly than other resistor materials and has some limitations in high temperature applications. Manganin has a wide range of uses in applications requiring precise measurement and calibration.

ZERANIN

ZERANIN is a high-performance resistor material consisting of copper (Fr), manganese (Mn) and tin (Sn) alloy. With its low temperature coefficient (±20 ppm/°C) and high stability, it is widely used in applications such as precision measuring devices, reference resistors and shunt resistors. The low thermoelectric power coefficient (about 1 µV/°C) and corrosion resistance make ZERANIN ideal for precise and long-term measurements. It offers low TCR, high stability and longevity, while it can be more costly than other resistor materials and has some limitations in high temperature applications. ZERANIN has a wide range of application in the electrical and electronics industry.

ISAOHM

ISAOHM is an alloy consisting of nickel (Ni), chromium (Cr), aluminum (Al), silicon (Si) manganese (Mn) and iron (Fe) elements. It is a high-performance resistor material brand used in precision measurement and calibration applications. It has some specific characteristics such as low temperature coefficient (TCR), high stability, low thermoelectric power and high corrosion resistance. It is usually used in precision measuring instruments, reference resistors and calibration equipment. Its advantages include low TCR, long service life and reliable performance, while it can also be more costly and have some limitations in high temperature applications.

NOVENTIN

The recently developed NOVENTIN, consisting of copper (Cu), manganese (Mn) and nickel (Ni) alloy, closes the gap between it and MANGANIN with its high relative electric resistance. It is a special resistor material used in applications that require high precision and stability. It has some specific characteristics such as low temperature coefficient (TCR), high stability, low thermoelectric power and high corrosion resistance. It is widely used in precision measuring devices, reference resistors and calibration equipment. Its advantages include low TCR, long service life and reliable performance, while it can also be more costly and have some limitations in high temperature applications.

Since these properties are influenced by both the resistor material used and the design and technology, two different manufacturing technologies have been developed. ISA-PLAN and ISA-WELD.

Manufacturing Technologies Used by Isabellenhütte:

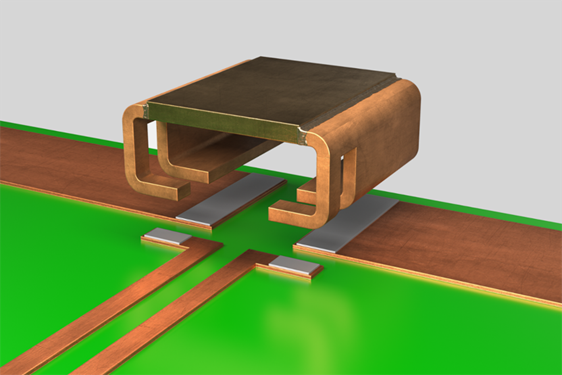

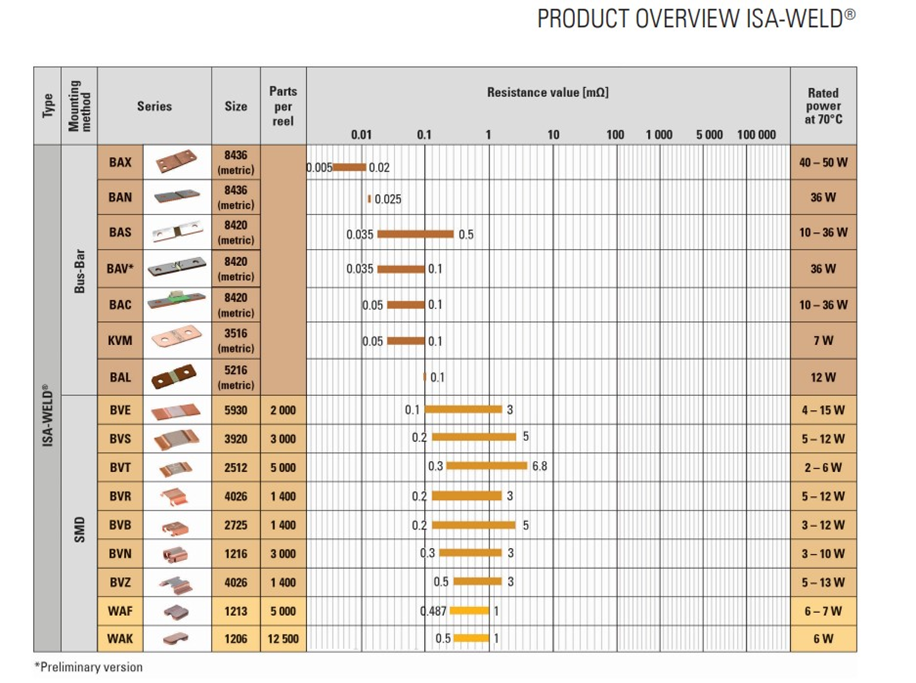

ISA-WELD

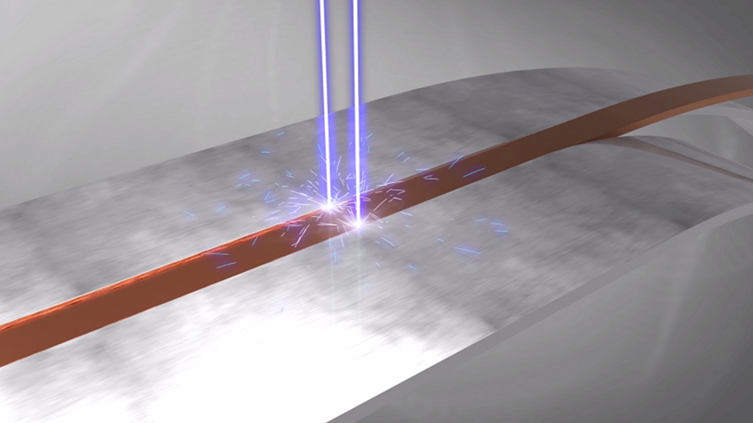

ISA-WELD technology is a welding method developed specifically for applications that require high precision and reliability. This technology is widely used in electronics and microelectronics industries, medical device manufacturing, aerospace industry, automotive industry and several other fields.

Basic Features of ISA-WELD Technology:

- Sensitivity: The ISA-WELD is ideal for welding operations that require high precision. It allows welding on a micro scale.

- Reliability: This technology guarantees that the welding joints are of high reliability. It creates strong and durable joints in the welding zones.

- Material Compatibility: It can be used to weld different types of materials. It is especially effective in welding thin materials.

- Low Thermal Effect: ISA-WELD creates a low thermal effect during the welding process. In this way, the structural integrity of the materials is maintained and the risk of deformation is reduced.

- Automation and Control: It offers a high degree of automation and control. This increases the repeatability and manufacturing speed.

Areas of use:

- Electronics Industry: It is used for welding microchips, circuit boards and other electronic components.

- In Motor Drives: It is used to control the speed, torque, load and direction of electric motors.

- Battery Charging Systems: It is used in battery charging systems that require reliability and stability.

- Energy Measurement: It is used in systems where sensitivity and tolerance are required.

- Automotive: It is preferred in the automotive industry for the manufacturing of parts that require precise and durable welding.

ISA-WELD technology plays a major role in several industrial applications that require precision and reliability. This technology, constantly being developed as part of advanced manufacturing techniques, caters for a wider range of applications.

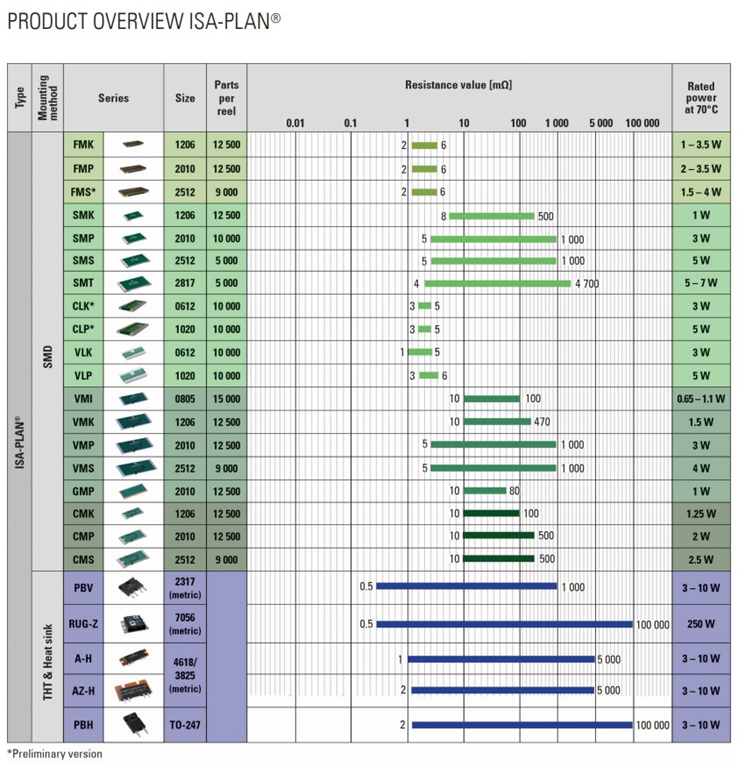

ISA-PLAN

ISA-PLAN technology is a manufacturing technology used in the manufacture of precision measuring devices and sensors. This technology has been developed specifically for applications that require high precision, accuracy and reliability. ISA-PLAN technology is widely used in areas such as industry, automotive, medical devices and electronics.

Basic Features of ISA-PLAN Technology:

- Sensitivity: It offers high precision and accuracy, allowing the measuring instruments and sensors to give reliable results.

- Durability: The materials and methods used in the manufacturing process ensure that the devices are long-lasting and durable.

- Thin Films: The ISA-PLAN uses thin-film technology, which allows devices and sensors to be small and light.

- Stability: It offers high stability, ensuring that the measurement results are repeatable and consistent.

- Various Applications: It can adapt to different applications, which makes it possible to use it in a wide range of industries.

Areas of use:

- Industry: It is used to manufacture sensors for pressure, temperature and flow measurements.

- Automotive: It is widely used in the manufacturing of various sensors (such as engine control sensors) used in vehicles.

- Medical Devices: It is used in the manufacture of medical measuring devices (such as blood pressure monitors).

- Electronics: It is preferred in the manufacturing of sensitive sensors and components used in electronic devices.

- Aerospace: It is used in aerospace components that require high strength and reliability.

Advantages of ISA-PLAN Technology:

- High Performance: It guarantees the high performance of the devices and sensors.

- Flexibility: Since it is compatible with different materials and manufacturing techniques, it can easily adapt to various applications.

- Cost Effectiveness: It helps to reduce costs by optimizing the manufacturing process.

- Advanced Design: Thin film technology allows for designing more compact and light devices.

ISA-PLAN technology plays a major role in the manufacturing of precision measuring devices and sensors. It offers a reliable solution in applications that require high precision, accuracy and durability. This technology is constantly being developed to meet today’s industrial needs.