What is the Clean Room Application?

Clean room application is a method usually used in the manufacturing or processing stages of sensitive products. This application is actually a special room or area designed to minimize dust, particles, microorganisms and other pollutants in the environment. A clean room provides an environment controlled at a certain standard and this environment is used to improve the quality and reliability of products.

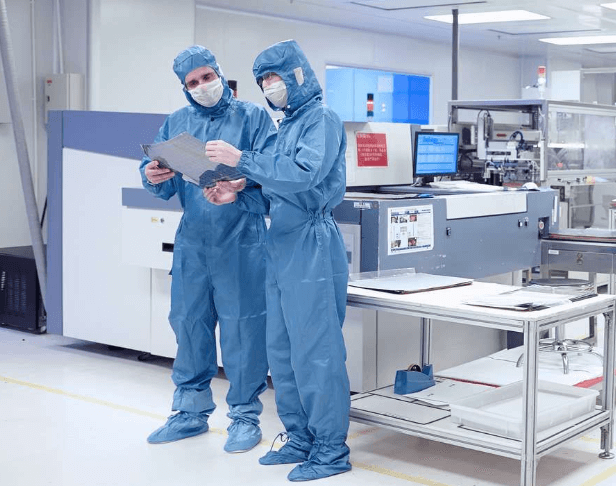

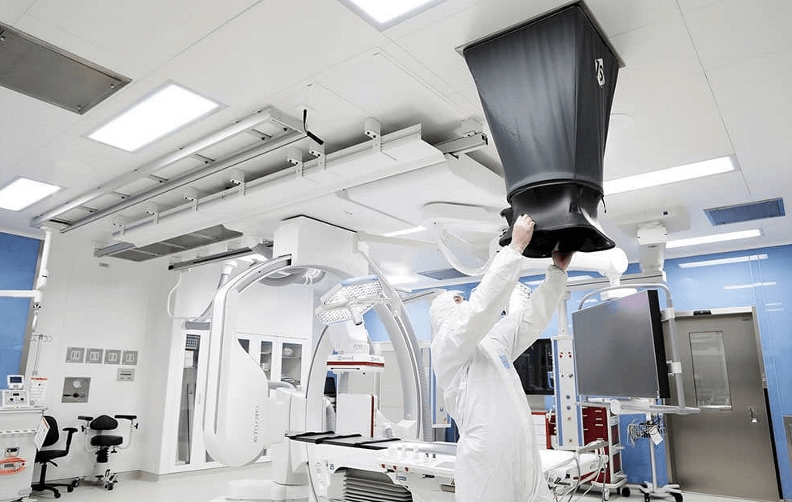

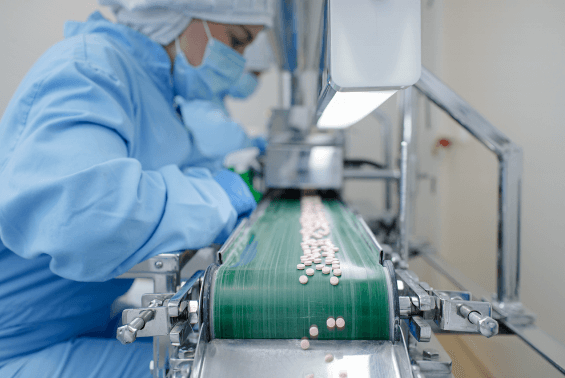

The clean room application is mainly used in electronics, pharmaceutical, food, optics, biomedical and semiconductor industries. In these industries, it is extremely important that the products are protected against external factors during the manufacturing process and are not contaminated.

The clean room application includes a number of techniques and procedures, such as special filtration systems, air circulation control, and wearing appropriate PPEs. This ensures the preservation of a clean environment and keeps the quality of the products at the maximum level.

Why Do We Need a Clean Room?

There are several reasons why the clean room application is needed:

Product Quality: It is necessary to minimize external contamination during the manufacturing or processing of sensitive products. Clean room applications provide quality control by increasing the quality of the products.

Process Security: It is crucial in specific industries, the pharmaceutical and food sector in the lead, that the products are manufactured in a clean and sterile environment. Clean room applications ensure that the products are manufactured hygienically and safely.

Compliance with Standards: There are certain standards and regulations in many industries. Clean room applications ensure compliance with these standards and regulations and help to make a smooth transition during inspections.

Dust and Particle Control: Some products, especially those in the electronics and optical industries, may be adversely affected from dust and particles. Clean room applications improve the quality of products by keeping dust and particle levels under control.

Microorganism Control: In some industries, the biomedical and pharmaceutical industries in the lead, the transmission of microorganisms to the products can pose serious health risks. Clean room applications prevent microorganism contamination and ensure the safety of products.

Why are Clean Room Applications Important in Electronics Manufacture?

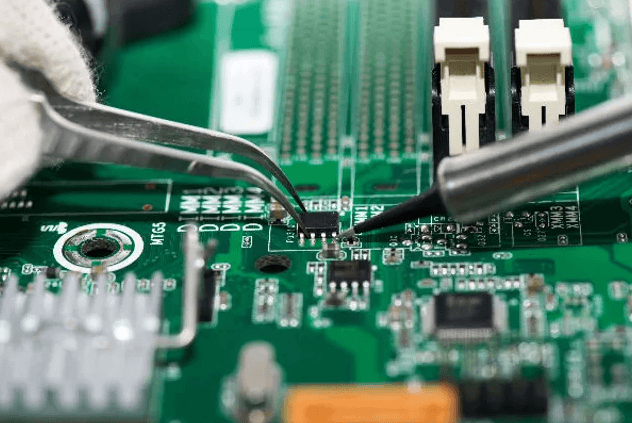

Dust and Particle Control: Dust and particle contamination on the products during the manufacture of electronics causes static electrification, resulting in short circuits between components or malfunctions. A Clean Room improves the quality of the products and ensures safety.

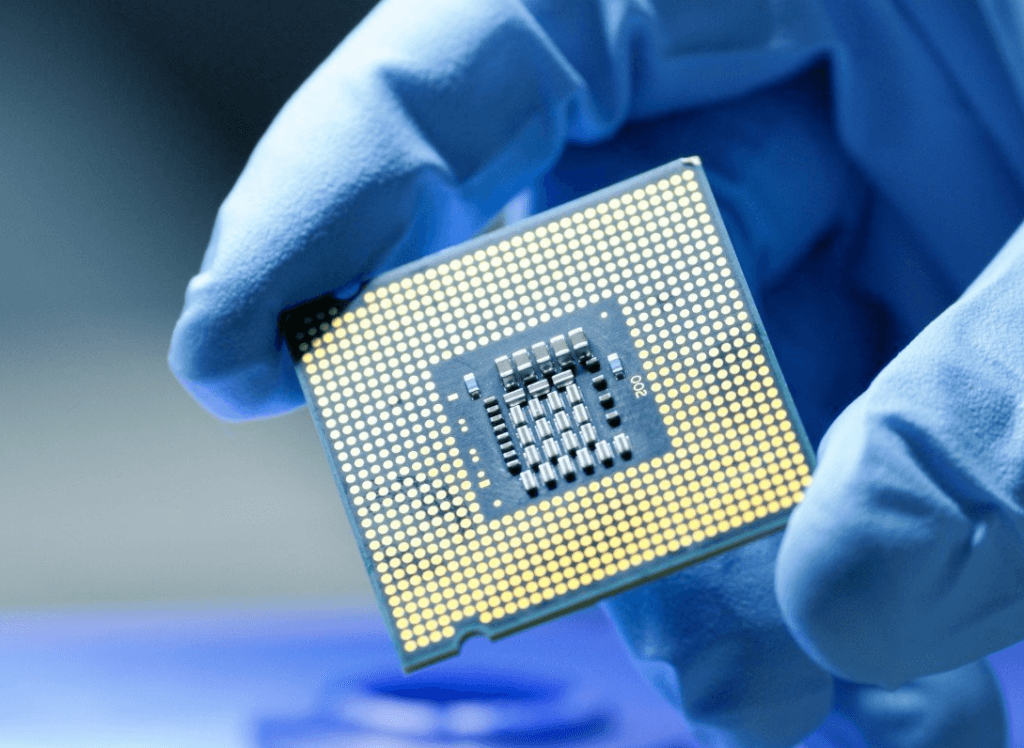

Microchip Manufacturing: In the semiconductor industry, even the smallest contaminant during the manufacture of microchips and other integrated circuits can affect the performance of the device. The Clean Room provides the sterile and controlled environment necessary for such sensitive manufacturing environments.

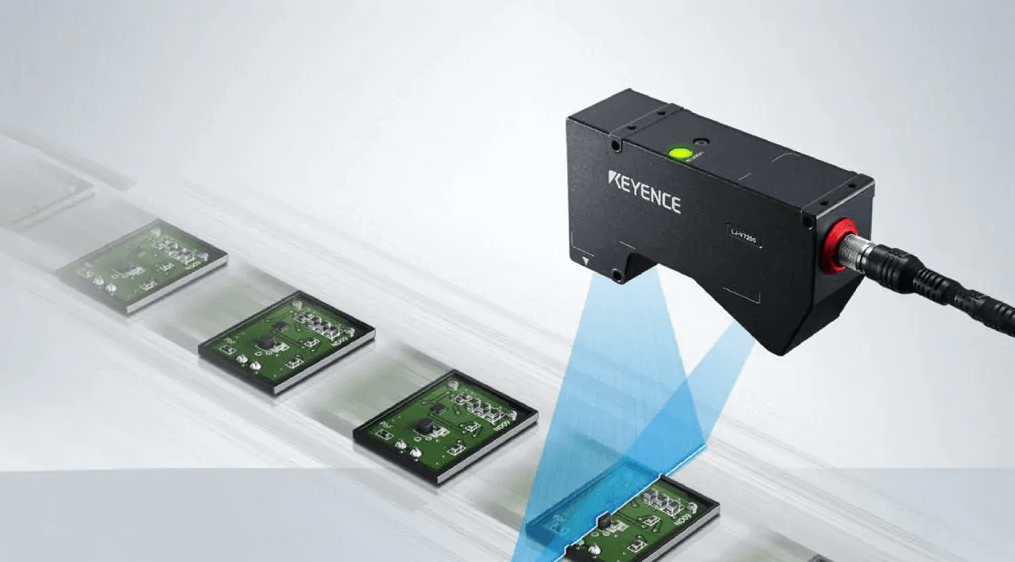

Precision Measuring Devices: Electronic devices, such as optical and laser-based precision measuring devices, should be minimally affected by external factors. The clean room increases the safety of sensitive measurements by ensuring the correct operation of these devices.

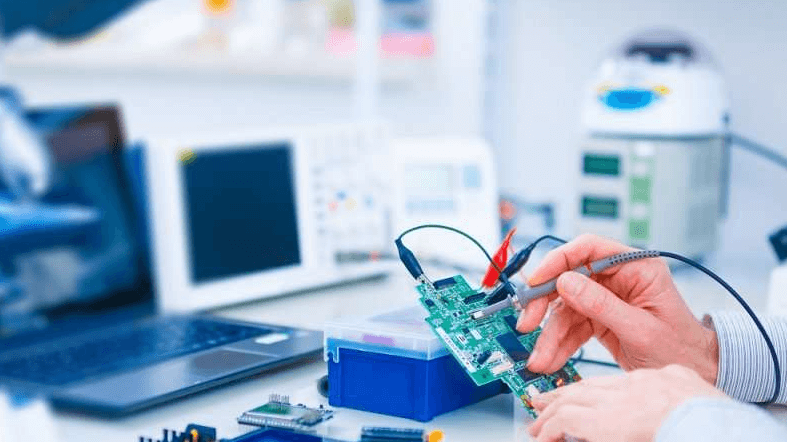

Electronic Assembly and Testing: During the installation and testing of electronic components, working in a clean environment improves both the quality of products and the reliability of final products. It helps to minimize possible errors.

Compliance with Standards: The Electronics Industry is usually subject to certain standards and regulations. Clean room applications comply with these standards and guarantee the quality and reliability of products.