Silicon carbide (SiC) is an important material. It is a composite material consisting of silicon (Si) and carbon (C) elements. Silicon carbide (SiC) is a semiconductor material that is widely used, especially in high temperature and high-power applications.

Silicon carbide (SiC) offers high performance thanks to its crystal structure. SiC has a quadrilateral chain crystal structure, which allows electrons to move at higher speeds and operate under higher temperature and voltage.

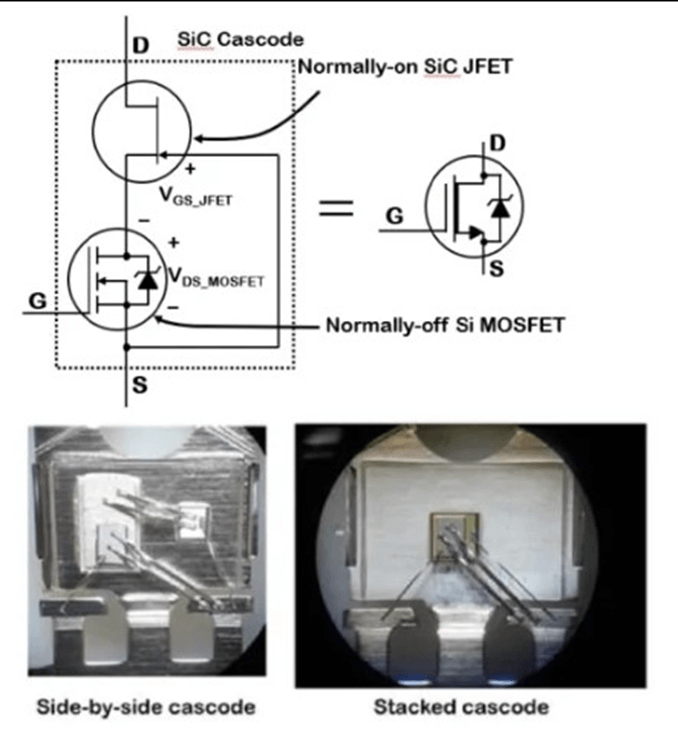

Silicon Carbide (SiC) FETs offer many advantages and some of their properties are superior to traditional silicon-based FETs. The specific features of SiC FETs are:

High Temperature Tolerance: SiC is a semiconductor material that can work stable even at high temperatures. With this feature, SiC FETs offer reliable performance in high temperature applications.

High Energy Efficiency: SiC FETs can operate with lower conductivity and switching losses than traditional silicon-based FETs. This improves energy conversion efficiency and reduces energy costs.

High Frequency Performance: SiC FETs can show high performance even at high switching frequencies. This gives the advantage for faster switching and more compact designs.

RDS(ON) Resistance: SiC FETs can have a low “ON” resistance. This translates into higher power density and less heat generation.

Ease of Thermal Management: The high temperature tolerance and low thermal resistance of SiC FETs make thermal management easier. This also offers more flexibility in the system design.

Compact Design: With their high performance and energy efficiency, SiC FETs allow for designing more compact power electronics systems.

How Will Silicon Carbide (SiC) FETs Play a Role in the Electrification of Vehicles in the Future?

Today, as we are making a transition towards a sustainable economy to reduce environmental impacts, it is obvious that transportation will play a major role. Silicon Carbide (SiC) semiconductor technology plays a critical role in this transformation by improving energy efficiency and accelerating electrification. SiC FETs can increase the range of electric vehicles (EV), shorten charging times and pose an alternative to combustion engine vehicles in dense urban areas.

The designers of electric vehicle subsystems have the option to choose from a variety of SiC power products. These products are available for many different applications, from inverters to on-board chargers. The adoption of SIC allows vehicles to be lighter, more efficient and have a longer range.

The distribution infrastructure of electric vehicles is also important, and SiC components need to be used for highly efficient, low cost and fast charging. In addition, both the vehicles and chargers are switching from 400V to 800V to improve energy efficiency.

Silicon Carbide (SiC) FETs have great potential to play a major role in the electrification of vehicles. The use of SiC FETs in the energy conversion, power distribution and driving control systems of electric and hybrid vehicles offers a number of advantages:

Increased Efficiency and Range: SiC FETs can extend the vehicle range by increasing energy conversion efficiency. Higher efficiency allows for more efficient use of battery capacity.

Fast Charging: The high switching frequencies of SiC FETs can be compatible with fast charging technologies. This allows the vehicles to be charged in a shorter time.

Compact Design: The SiC FETs allow for designing more compact and lightweight power electronics systems. This, in turn, can help vehicles take up less space and become lighter.

High Temperature Tolerance: The temperature in a vehicle can increase under many conditions. The high temperature tolerance of SiC FETs helps to make vehicles more reliable and durable.

Low Thermal Losses: Low conductive and switching losses not only allow the vehicles to generate less heat but also simplifies the thermal management. This can also extend the life of the battery and other components.

High Power Density: SiC FETs allow for higher power density, which provides the potential for more powerful and high-performance electric motors and other power electronics components.

These advantages point that SiC FETs will play a critical role in improving the performance, efficiency and reliability of electric and hybrid vehicles. Therefore, the automotive industry is increasingly beginning to adopt SiC FETs in power electronics systems and innovative technologies in electric vehicles.